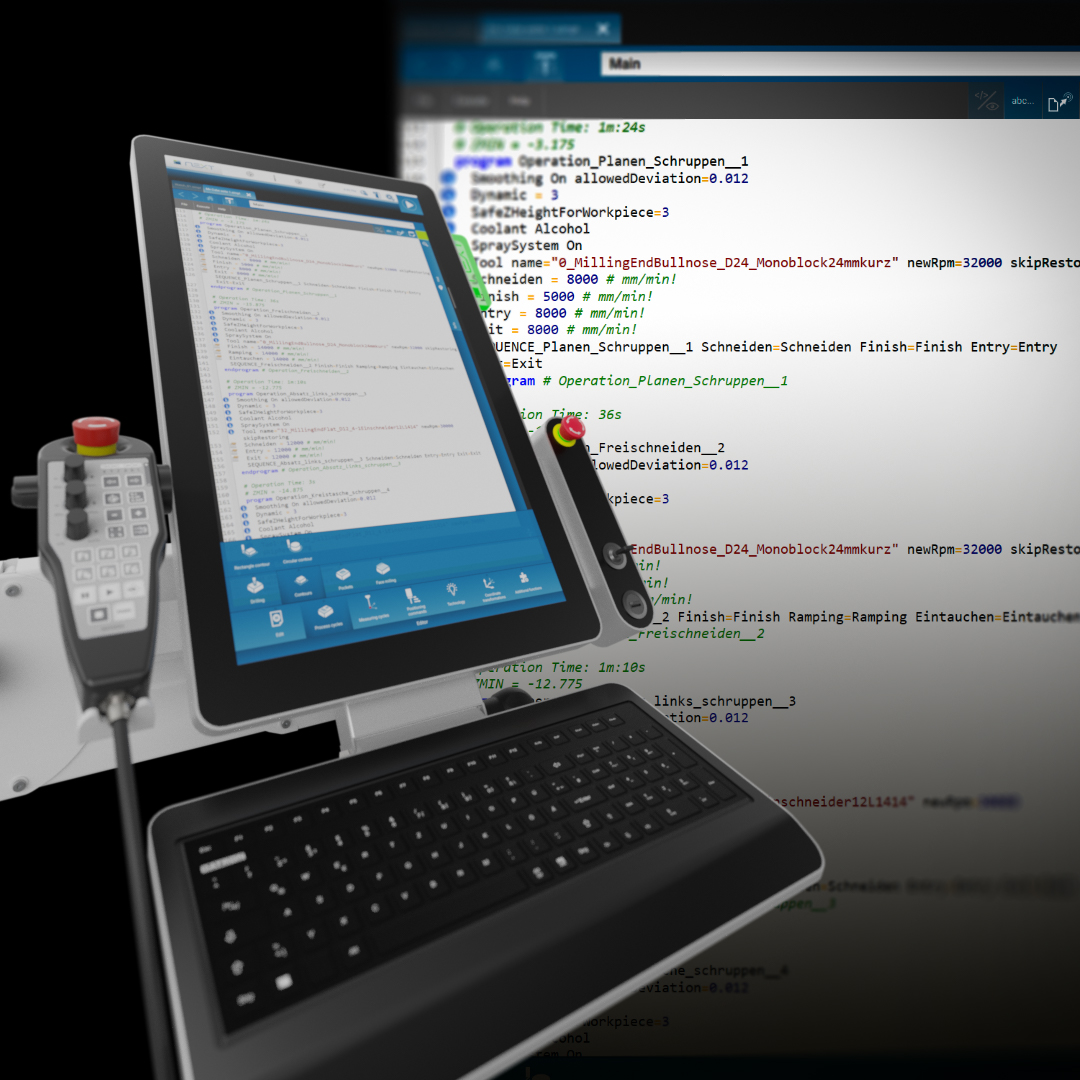

Based on the plug-and-play principle, DATRON industrial milling machines from now on can be easily controlled via our easy-to-understand control Software DATRON next. Using swiping gestures known from operating a smartphone, DATRON next makes milling almost as easy as 3D printing. In few steps, the operator is actively guided through the milling program providing assistant functions and an integrated camera. Self-explanatory icons and tools, components, etc., depicted closely to reality, support a fast identification of various functions and offer a high degree of recognition.

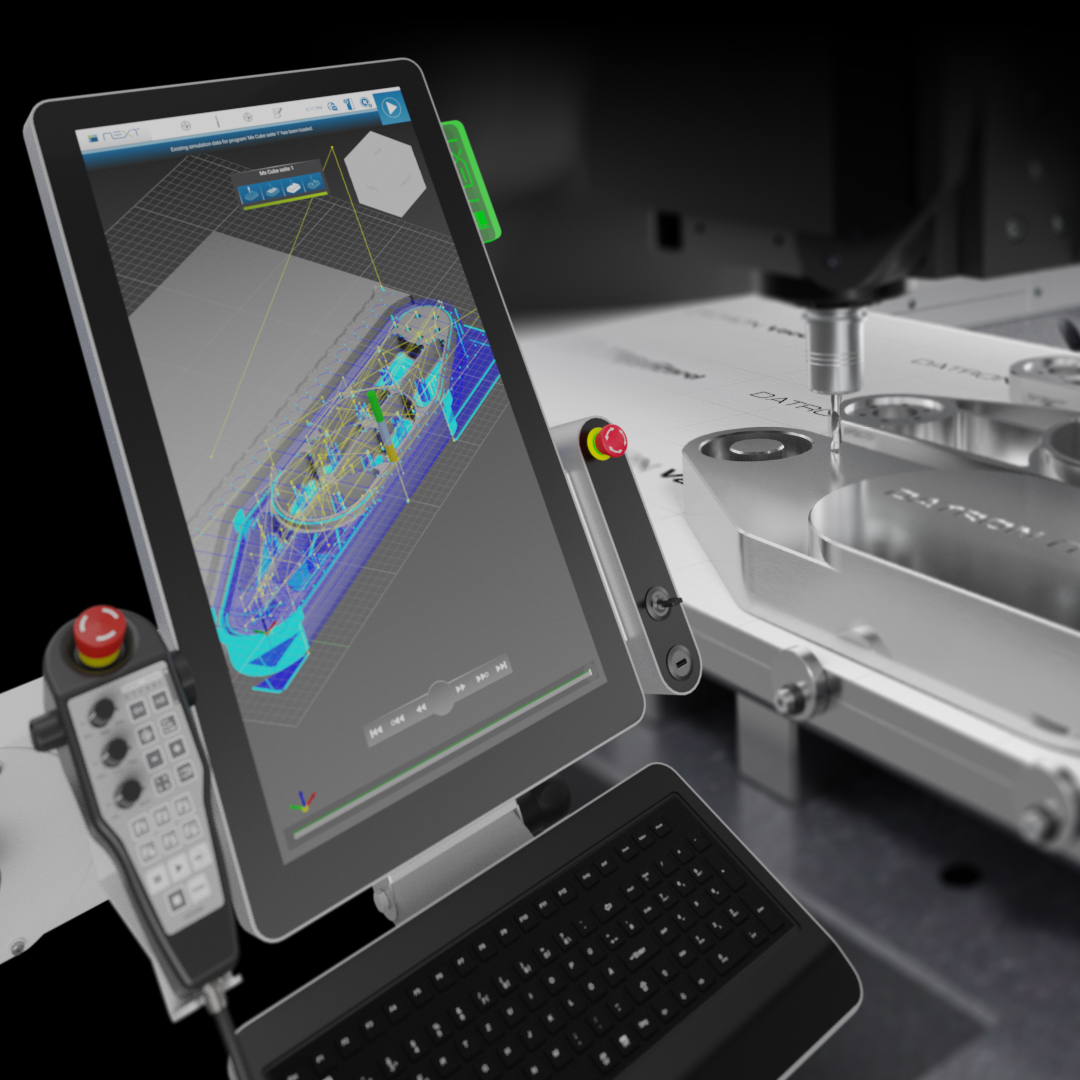

The absolute highlight of the machine is the combination of the camera in the machine interior with the sensitive multi-touch display and an XYZ sensor. This allows the user to easily set the zero point of his workpiece by means of swiping gestures and replaces a time-consuming manual input of complex numerical data. In addition, the operator is given the opportunity to simulate the milling process in advance in 3D and, if necessary, can add corrections. After a quick set-up of the workpiece, the user can rely on the proven quality of DATRON high-speed milling.

Function for the visual setup of the workpiece orgin. It is used for very fast, simple and at the same time safe setup of your workspace.

For measurement and automatic compensation of unevenness in the workpiece surface.

To set up individual areas in the machincing room which must not be approached by the tool.

For wear monitoring and automation of the tool replacement during machining.

For the production of several indentical workpieces from a single blank and for the serial execution of a program at different origins.